1. Automobile fine dust

Incomplete combustion means that less fuel is burned… Complete combustion means that the fuel is completely burned when it is burned. If sufficient air, i.e. oxygen, is supplied here for combustion, only carbon dioxide and hydrogen are produced.

Incomplete combustion is a phenomenon in which the fuel is not completely burned and soot or carbon monoxide is generated when the supply of oxygen is insufficient or the temperature is low when a substance is burned. This is the cause of fine dust emissions such as soot, carbon monoxide, and hydrocarbon emissions from automobile exhaust fumes.

2. The world's first 'bio-ceramic bar' - Aero 88

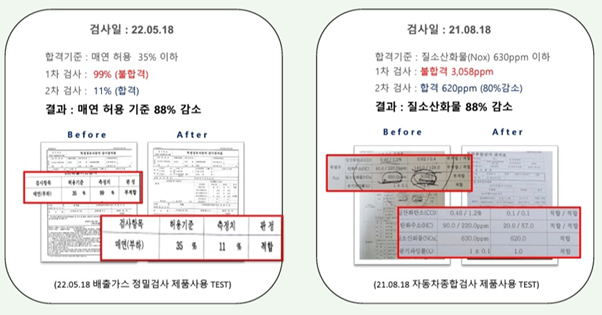

Aero 88 emits far-infrared wavelengths of 7~14um and generates negative ions to split fuel particles (clusters) and improve fuel efficiency and combustion. In other words, it separates hydrogen and carbon contained in fossil fuels and induces complete combustion. This reduces Nox, a carcinogen in automobile exhaust fumes, by more than 60~80% and also has a fuel efficiency saving effect of about 25%.

In particular, in the case of diesel engines using DFP (Diesel Particulate Filter, pollution reduction device) and urea solution, unnecessary fuel consumption and use of catalysts reduce output, nitrogen oxide concentration does not decrease, and the cost of urea solution is not small. In the case of Korea, 4 to 10 million won per unit and more than 500 billion won in national taxes are invested annually, and 500,000 won and continuous urea solution costs are spent for individuals, while 'bio ceramic bars' can replace this at a cost of about 350,000 won.

2018 ESM Korea Consumer Evaluation Excellent Environment Award

2020 KAPA Vehicle Fine Dust Reduction Body First Recognition

2022 National Safety Disaster Association Environmental Safety Product

Carbon dioxide produced by incomplete combustion is the biggest cause of environmental pollution.

When a passenger car drives 1km, 237.9g of carbon dioxide is emitted, and when an average of about 35km is driven per day, 8.53kg per car. The total number of passenger cars in Seoul, Korea is 16,714 tons, and 6,100,645 tons are emitted annually. A pine forest of about 3,000 pyeong absorbs 12.4 tons of carbon dioxide annually, and for a pine forest of about 6,100,645 tons of carbon dioxide to absorb, it would take 14,759,625,000 pyeong... about 8 times the size of Seoul.

This is why ‘bioceramic bar’ technology is needed.

3. Introduction to Patented Technology

The present invention relates to an 'anion generator for reducing fine dust and its manufacturing method', wherein anion generator is manufactured using a first powder composed of silicon dioxide and aluminum and a second powder composed of titanium and zirconium, and far-infrared rays generated by the fusion of anions generated from the second powder and elements generated from the first powder break the multi-ring structure, thereby significantly reducing fine dust generated when burning fuel. In addition, when the anion generator is inserted inside a fuel tank, the anions generated from the second powder and the oxygen inhaled during fuel combustion completely combust the fuel through an oxidation reaction, thereby reducing soot and increasing fuel efficiency. [Problem to be solved]

in the patent is that the negative ion generator for reducing fine dust according to the present invention to achieve the above purpose is an negative ion generator accommodated in a fuel tank of an internal combustion engine to reduce fine dust in exhaust gas, and the negative ion generator is characterized by being formed by mixing 60% of a first powder composed of silicon dioxide and aluminum oxide and 40% of a second powder composed of titanium and zirconium.

One side of the above negative ion generator is characterized by having a catch hole formed on which a wire is connected so that the negative ion generator inserted into the fuel tank can be extracted from the fuel tank. One side of the above negative ion generator is characterized by having a knurled portion protruding in a predetermined shape so as to increase the contact surface between the fuel and the negative ion generator.

It is characterized by being formed. In the manufacturing method of the above negative ion generating sphere, the negative ion generating sphere is characterized by comprising a grinding step of grinding silica, feldspar, and aventurine containing silicon dioxide and aluminum oxide into a first powder of 2000 mesh; a mixing step of creating a mixture by mixing 60% of the first powder and 40% of the second powder; a kneading step of creating a dough by adding water to the mixture; and a firing step of putting the dough into a set mold and firing it at a temperature of 1100°.

[Effects of the invention] First, by

inserting an anion generator using a second powder composed of titanium and zirconium into the fuel tank, the fuel is completely combusted through the oxidation of the anions generated from titanium and the oxygen inhaled during combustion of the fuel, thereby reducing smoke and increasing fuel efficiency.

Second, by manufacturing an anion generator using a first powder composed of silicon dioxide and aluminum oxide and a second powder composed of titanium and zirconium, the anions generated from the second powder and the elements generated from the first powder are fused together to form far infrared rays that break the multi-ring structure of the benzene ring structure, thereby significantly reducing fine dust generated when burning fuel.

Third, by forming a hook hole on one side of the anion generator to which a wire can be hung, the anion generator inserted into the fuel tank can be safely removed, thereby preventing damage to the anion generator product in advance.

Fourth, a number of knurlings are formed on one side of the anion generator. By being formed, the contact surface between the fuel and the negative ion generator increases, so that the far infrared rays and oxidation reaction generated by the contact between the fuel and the negative ion generator can be significantly increased.

4. Business feasibility

This patented technology has been recognized for its effectiveness in the 2018 ESM Korea Consumer Evaluation Excellent Environment Award, the first recognition as a vehicle fine dust reduction body by the 2020 KAPA (Korea Automobile Parts Association), and the 2022 National Safety Disaster Association environmental safety product.

However, during the commercialization process as an automobile 'fine dust reduction device', there was a problem in commercializing the product because smoke was not significantly generated when driving at 1,500 RPM. It is like the alternative market worth 500 billion won every year has stopped.

As an alternative, it will be commercialized as a fuel incomplete combustion supply device like 'Bullsone Shot' from 2025 . That is, Bulls One Shot (2024 sales of 148.2 billion won, net profit of 10 billion won) is composed of a device that helps burn fuel well through the negative ions generated from the first powder made of silicon dioxide and aluminum and the second powder made of titanium and zirconium, and the oxidation of oxygen inhaled during fuel combustion, just as it chemically decomposes the hardened carbon deposits accumulated in the fuel injection system and air intake system of the engine when put into the fuel inlet when putting fuel in the car, thereby facilitating the intake of air and increasing combustion efficiency. (Fluorine One Shot: Cleansing power of 60-80% for general vehicles and 75-80% for GDI vehicles, improved fuel efficiency by an average of 2.8%, improved output by 2.81%, and reduction effects such as exhaust gas CO (-19.8%), THC (-10.4%), and NOx (-8.8%) are superior.)

This is why ‘bioceramic bars’ have high commercial value.

We are looking for investors to operate a joint production and sales company for 'Bio Ceramic Bar' in Korea and overseas.

Contact: +82-54-852-8090

E-mail: h8090@naver.com or mail@markethub.org